Applications

"De's Technico Ltd", widely known as "DE'S", started a journey four decades ago to provide Automatic Fire Protection Systems in India. Our mission met with warm welcome starting from hazardous areas in Oil Sector in the initial state to gradual expansion in sectors like Automobile, Power, Steel, Commercial buildings, Airports and so on. Certification of performance from our valued customers all over acts as blessings to our intense endeavor and astute vision.

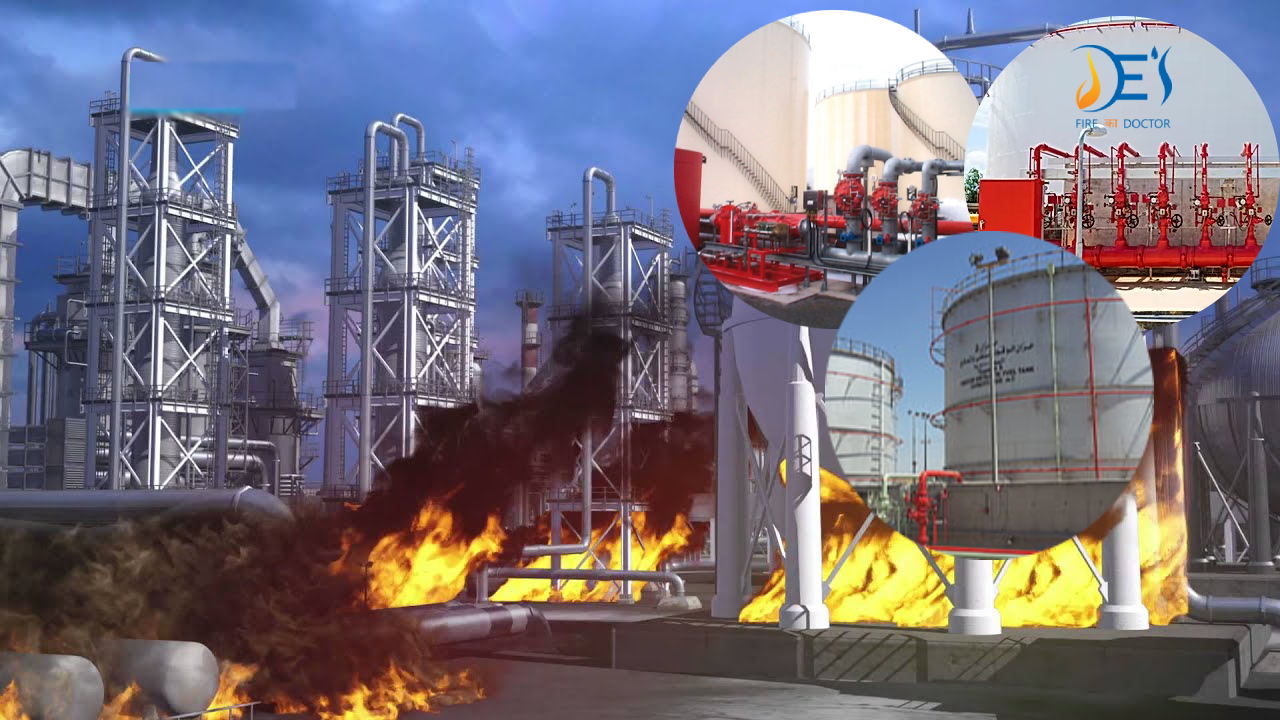

Oil & Gas, Petrochemical :

1. Foam bladder tank systems provide accurate, dependable, and cost-effective foam fire protection for a variety of flammable/combustible hazard areas, with no external power other than water pressure. Water is applied to the outside surface of the bladder, displacing foam the concentrate inside the bladder, which then is injected into the water stream.

2. Deluge valve water spray fixed systems for cooling of storage tanks, bullets, spheres, structures, and flammable liquid storage areas. These systems are designed as per NFPA 15. De's Technico deluge valves offer reliable and robust solutions. Deluge valves can be operated by manual, hydraulic, pneumatic or electric trims. DTL medium velocity nozzles come in a combination of k-factors and spray angles to offer effective spray pattern for cooling applications.

3. Fixed foam systems for open top floating and cone roof flammable liquid storage tanks. These systems are designed as per NFPA 11. DTL foam chambers and rim seal foam pourers cover a wide range of flow rates and offer effective foam discharge solutions, making these ideal systems for storage tank applications.

4. Custom engineered foam systems are ideal for foam proportioning applications for a range of foam discharge.

5. Range of monitors is used in petrochemical storage and refineries.

Power Plant :

1. Power plants are characterized by their complex systems consisting of many high-risk areas and therefore reliable fire extinguishing systems are essential to ensure the safety in such places.

2. High-velocity water spray nozzles for protection of fixed hazards such as transformers, circuit breakers, turbo alternators, lube oil systems, oil fired boilers, and similar hazards.

3. Coal is transported on encased conveyor belts that run across coal processing stations. Fire detection and medium velocity automatic deluge water spray systems are most suitable for protection of coal conveyor belts.

4.Steam and gas turbo generators operating at high temperature and speed contain large quantities of lubricating oil and constitute to a major risk of fire. Deluge water spray systems are commonly used in the protection of such machines.

5. Fixed water spray systems are designed as per NFPA 15.

Commercial & Residential Buildings, Hotels and Airports :

1. The pre-action system is used when it is required to have two triggers in order to start water flow through the sprinkler system. It greatly helps that the pre-action fire sprinkler can be set to prevent water from spouting in case of a false alarm or a mechanical failure. The pre-action system is good for use in places where the sprinklers are necessary in case of actual fire only so there is no water damage of any items in building due to inadvertent opening of sprinklers.

2. The automatic wet pipe fire sprinkler system is most common type of sprinkler system installed in buildings. Alarm valves act as check valves and to give an alarm in case of fire. The alarm is through water motor gong audible alarm bell or through a signal from pressure or flow switch.

3. This applies to commercial buildings, hotels, meeting rooms, logistics areas and production buildings or warehouses. In case of fire, the sprinkler system is automatically activated during the initial phase, thus preventing the fire from spreading. Sprinkler systems are designed in accordance to NFPA 13.