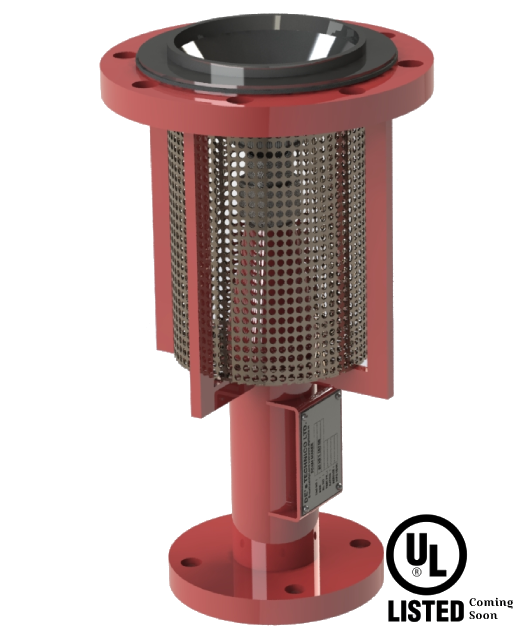

Foam Maker

Description

Applicable for Floating Roof Tank.

Suitable for all types of Foam Concentrate.

Inlet Size: 50,65 & 80 Nb

Working Pressure: 2.8 to 7 Kg/cm2

Maximum back Pressure: 1 PSI.

3 to 4% Foam Expansion.

Material: Carbon Steel with anticorrosive coating /SS 304/ SS 316

Flange: SORF, ASME B 16.5,150LBS, A105/ SS 304/ SS 316, MOC- A105

×

![]()

Products

Projects

Copyrights © 2026. All Rights Reserved to De's Technico Limited "Policies, Terms & Conditions "